Metallurgy

AHSL offers mechanical/metallurgical tests on metallic material and welded samples to determine the physical properties, identifying material grades, establishing the reliability of welder’s performance through Welder Qualification Tests, certify the weld procedures through Weld Procedure Qualification Tests.

Welded Samples, All kinds of fabricated structural, Oil & Gas, Marine, WPS, PQR, Welder Qualification Tests etc.., but not limited to the following:

- Tensile Test/All Weld tensile Test/Through Thickness tensile Test.

- Hardness Test – Vickers, Rockwell & Brinell hardness.

- Macro Examination on Weld coupon.

- Charpy impact Test for standard & Sub size specimens at ambient, Subzero and cryogenic temperatures

- Bend/Re-bend Test

- Flattening & Flaring Test.

- Pull out Test

- Fracture Test

- Proof Load Test on Nut.

- Nick Break Test.

- Compressive Load Test.

- Coating Thickness

- Ferrite Test

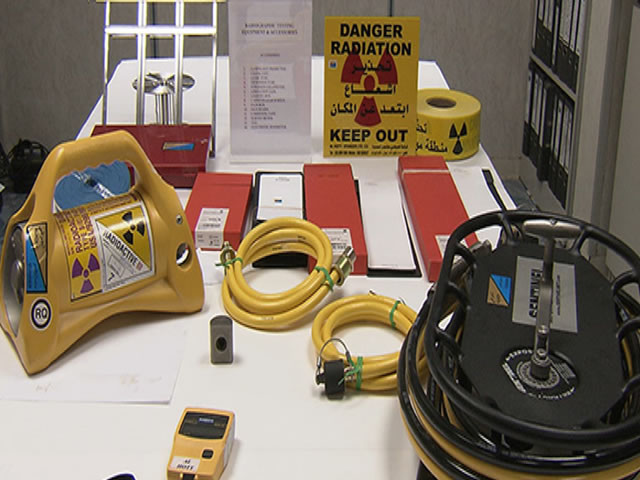

Non-Destructive Tests

AHSL provides Non-Destructive Testing (NDT) services pertinent to structural steel works, pipes, vessels, tanks and casting. NDT services are carried out in accordance with International Standards and Specifications like AWS, ASME, API, DNV, BV, LRS, RINA, etc.

AHSL has NDT Inspectors/Technicians with ASNT Level II qualifications for the following tests:

- Ultrasonic Testing (UT)

- Magnetic Particle Inspection (MPI)

- Dye or Liquid Penetrant Testing (DPT)

- Welding Inspection

- Visual Inspection

- Radiography Testing (Gamma ray & X – Ray)

- Ultrasonic Thickness Gauging (UTT)

- Radiography Film Interpretation (RTFI)

- Hardness Testing

- Positive Material Identification

- Pre & Post Weld Heat Treatment

- Ferrite Testing

- WPS & PQR Execution (Preparation of Welding procedure (PQR) and Welder Qualification Preparation)

Please Contact Us to discuss your testing program or specific requirement.